Eurobike in Frankfurt

Dear Customers and Friends:

Hard to believe but finally Strategic Sports is attending a trade show – a wait of 30 months - Eurobike in Frankfurt.

Visit Sherry and the Team at Hall 9.1 Booth E21. They are delighted to meet you after so many months! And if you are not visiting Eurobike – please contact us so we may present our latest models and catch up on the latest news.

These 2 years have been busy and challenging years facing the initial Covid lock downs and then the boom experienced by our industry. Then came rising costs and lack of shipping space. I will not list all the challenges as this is not the purpose. Suffice to say, in China, we continue to struggle with Covid lockdowns and so during these 2 years, we have not been sitting idle and have implemented a policy of decentralization as I outlined in last month’s South China Morning Post.

https://www.scmp.com/economy/china-economy/article/3179461/chinas-zero-covid-policy-has-some-manufacturers-asking-should (WORD FILE for a full story)

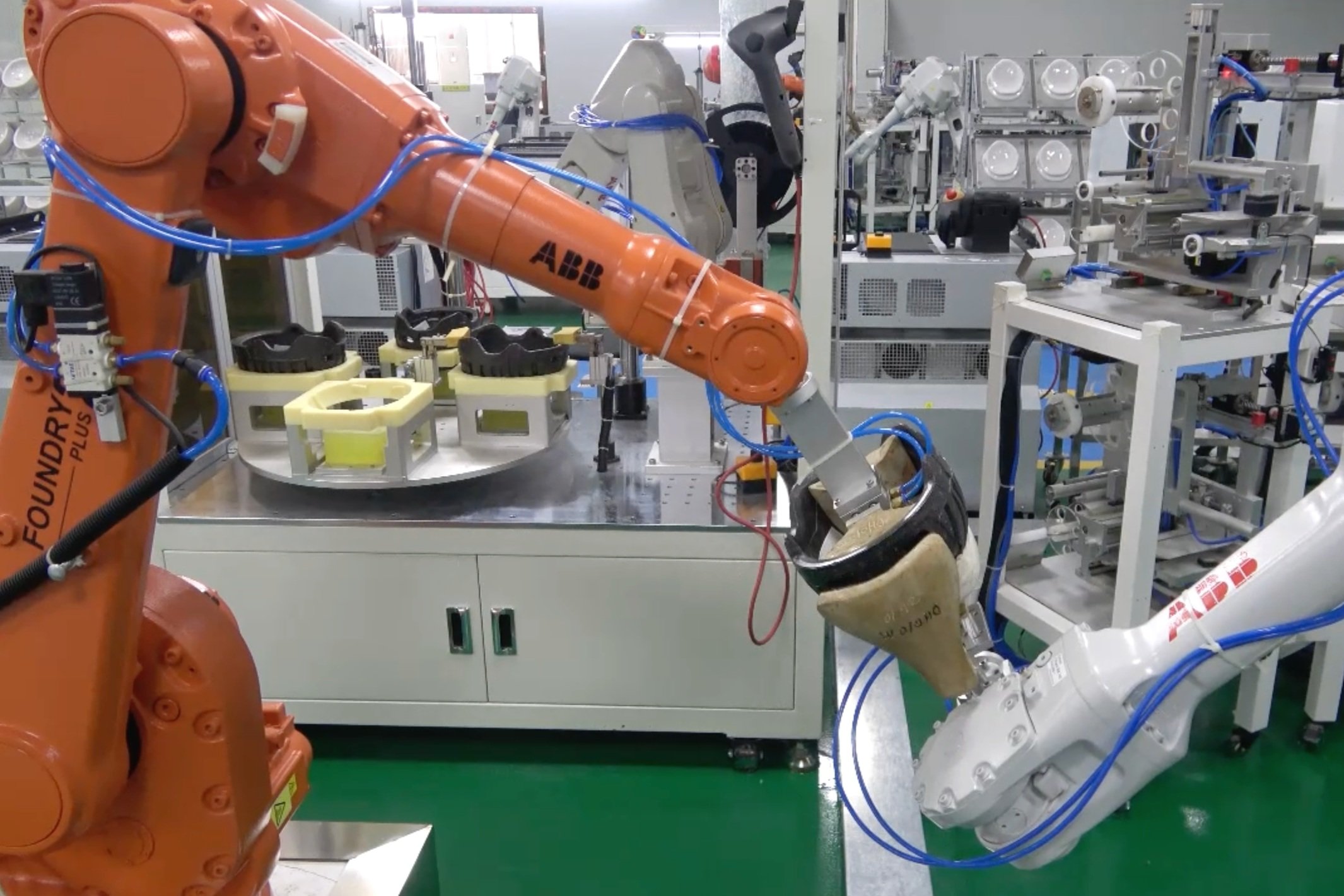

I am sure you are familiar with our Chasan, Dongguan factory which has 274 thousand square meters of production space where we produce all key elements of the helmets from shell, eps liners, paint, assembly in various compounds. In 2018, we had started an expansion factory in Huizhou – the city north of Dongguan – which has 71 thousand square meters of production space. The Huizhou factory was planned based on the principals of Industry 4.0 where machines communicated with each other and cutting edge automation.

Instead of the 8 - 12 person linear production lines, Huizhou has production units where most production steps are produced by robots and machines assisted by people. This factory was our dream as instead of various compounds where production processes are concentrated in one area, all production processes are in line and under one roof. This set up allows us to achieve our dream of 1 piece flow production style more common in automotive industries. The Huizhou facility also utilizes the latest in sustainability technologies and will be a large part of our effort to be carbon neutral.

One added benefit of separate facilities is that in the past, Dongguan was locked down, yet Huizhou was allowed to operate and later when Huizhou was under lock down, Dongguan had opened up. We realized by keeping separate supply chain, we could keep production running.

As the demand for production surpassed what Chashan and Huizhou both were able to produce, we cast our eyes to the other side of the Pearl River and partnered with an existing eps manufacturing facility. Where speed was of the essence, the facility had the latest German made eps press and we negotiated a partnership of their eps production facility and Pan Hong Factory Foshan was born in 2021. Pan Hong’s focus is on entry level glue on and inmold helmets utilizing 9000 square meters of production space.

With 3 separate zones, Strategic is ensured to continue production under the current China Zero Covid policy. And as each facility develops its own characteristics – there may be added benefits for one product to be made in a specific facility.

We would be delighted to explore the opportunities offered by each facility – not to mention the opportunities offered in our Portugal factory and soon to be in operations – Strategic Vietnam.

We thank you for your continued support as we faced past challenges. And we look forward to the future together.

Sincerely,

Norman Cheng

Managing Director

Strategic Sports Ltd.